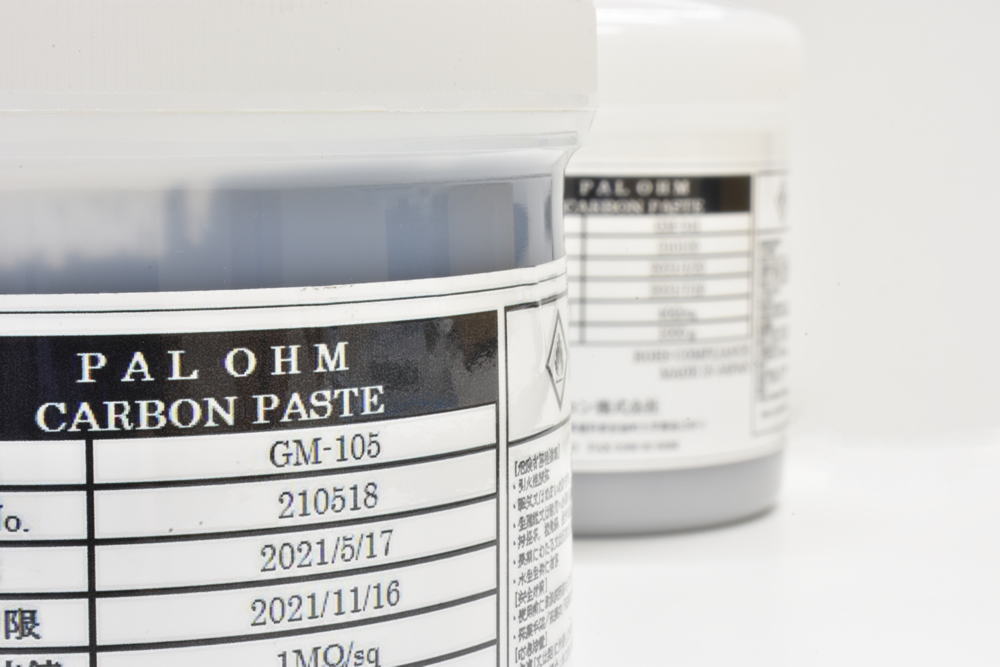

Our conductive carbon pastes are being used in circuit formation binding with phenolic resin (phenolic plastic). These are conductive inks for screen printing.

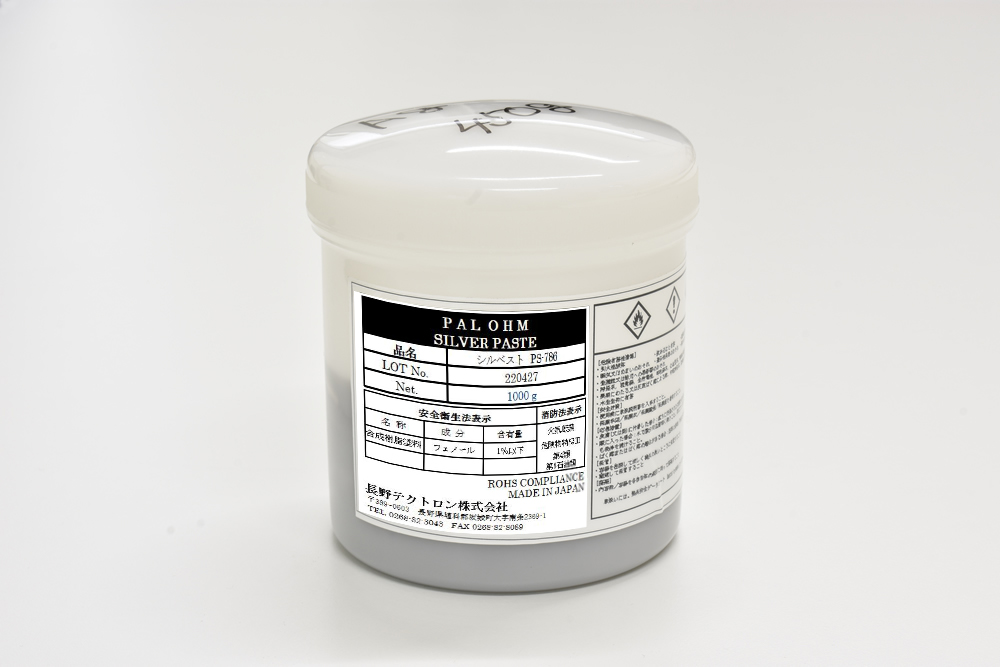

These conductive silver pastes are also used in our screen printing products.

Usage Condition

- Curing condition: 180℃ × 15 min.

- Maximum storage temperature 15℃ (last for 3 months)

Paste Preparation

The paste is a single part system. Gently stir before use. Avoid rapid stirring to prevent air entrapment during the stirring process. Once the paste has been removed from the container for printing, this may introduce contamination. Please do not put used paste back into the original container.

Clean-Up

Equipment can be cleaned using alcohols such as IPA or acetone.

Storage and shelf-life

To avoid dew condensation, open package only after returning to normal temperature. Stir well before using the product. Seperation may occur according to siler and binder weight difference. For this case, stir well until the color turn homogeneous, using like spatula. Keep immediately back to storage temperature after using.

Properties

| Test Item | Representative Valu | Method |

|---|---|---|

| Visibility | Silver-white viscous liquid | via visual observation |

| Viscosity (dPa.s/25℃) | 200 | Rion Visco Tester VT-04, #2 Rotar |

| Sheet resistivity (Ω/sq) | 0.091 | Printing on paper phenol PCB |

| Solvent resistance (%) | +1.25 | Change in resistance, isopropanol dipping 5 min. in isopropanol |

| Thermal resistance (%) | -0.76 | Change in resistance, dipped in solder (260℃ x 5s) |

| Solder resistance (%) | +3.90 | Heat resistance test after post-flux |

| Adhesion | Within 5 | Cross-cut test |

|

※ Above data is based on PS-786 ※ We accept customized spec. also. |

||